The need for alternative fuels is a well-known fact. Seatech Engineering with a response to the growing need of building a fleet of LNG units.

In the dynamic world of marine engineering and the growing importance of green energy, the role of ship design offices cannot be overestimated. They serve to materialize the shipowner’s requirements and seek efficient and cost-effective solutions that meet the needs of the changing market, comply with the growing environmental criteria and support the sustainable development of maritime transport.

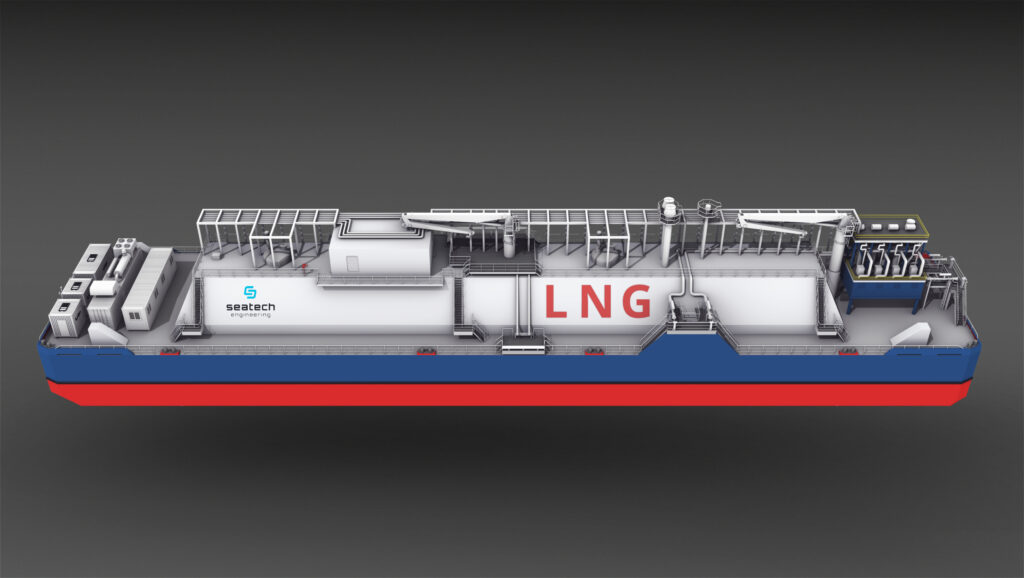

SE-619 Pocket FSRU for use in small ports along the Polish coastline, design by Seatech Engineering

The development of storage and regasification units, as well as bunkering vessels and feeders for LNG and other fuels, represents a significant step forward in the maritime industry’s quest for cleaner and more sustainable fuel solutions. Behind the scenes of these innovative vessels is a multileveled, precise design process that integrates cutting-edge technology, rigorous safety standards and environmental considerations. Seatech Engineering, a design office with more than 20 years of experience with projects for clients around the world, is carrying out FSRU (Floating Storage and Regasification Unit) conversions and tailor-made LNG bunkering unit designs as one of its flagship lines.

LNG retrofits at a price

Today, FSRUs represent an important part of the LNG supply chain, but with the ever-increasing demand for LNG and the lack of available resources, upgrading and adapting existing conventional LNG carriers to FSRUs is a valuable alternative, offering many benefits and real savings compared to building a unit from scratch. Seatech Engineering has extensive experience in the conversion of LNGCs (Liquified Natural Gas Carriers) to FSRUs and FSUs (Floating Storage Units), as well as in working with key suppliers of regasification and liquefaction systems. The office has built its expertise in unit retrofits mostly thanks to long-standing cooperation with Wartsila Gas Solutions, carrying out gas carrier conversions for international shipowners together.

Projects completed by Seatech confirm that the conversion of older LNG carriers to modern FSRUs provides a significant reduction in lead time.

Time from signing the contract to the final commissioning of the finished vessel can be reduced to two years. The bottleneck here may be the waiting period regarding necessary regasification equipment, but key preparations can be carried out in the meantime, and the final installation at the repair yard can be limited to a maximum of six months. For projects in our home market, FSRU conversion can be done locally at a selected Polish large shipyard, where most of the work is carried out by our local experienced companies. However, the shipyards shall have dedicated docks and adequate lifting capacity, as some elements, such as the regasification module, should be installed entirety. For example, a module with a capacity suitable for a “Polish FSRU” is about 750 tons in weight, explains Krzysztof Czerski, Head of LNG & Energy Department at Seatech Engineering.

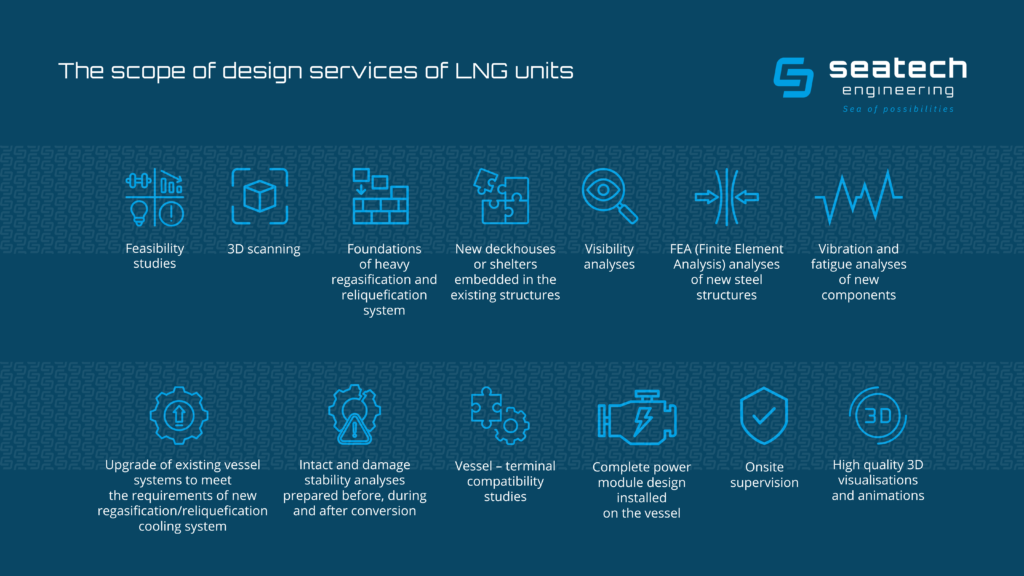

In comparison, the time to build a new FSRU in Korea, or in China, is currently between 4 and 5 years after signing a contract. FSRU modernization therefore demonstrates economic viability by repurposing existing vessels, offering a cost-effective and faster solution for LNG infrastructure expansion. However, it is worth mentioning that the resources of older conventional LNG carriers that can be converted are shrinking year by year. It is therefore likely that the only possible solution in the quest to meet LNG demand will be to build units from scratch. Regardless of the choice of FSRU implementation, the design process will play a key role here, providing solutions that optimize efficiency, responsiveness and sustainability in the changing landscape of energy operations, and Seatech Engineering office provides a full range of design services in this area.

Bunkering vessels and feeders as the buckle of the whole process

LNG/multi-fuel bunkering vessels and feeders are an integral part of the overall process of meeting the growing demand for LNG and other alternative fuels. The design process for such units begins with a comprehensive assessment of the vessel’s operational requirements and market needs. Design offices work closely with ship owners, operators and stakeholders to define key specification frameworks, including capacity, range, speed and compatibility with different fuel types. This initial phase is a key variable for subsequent design decisions, ensuring compliance with industry needs and regulatory standards.

One of the basic considerations while designing LNG and other alternative fuels bunkering units is safety. LNG, while offering environmental benefits, presents unique challenges due to its cryogenic nature and flammability. Engineers are employing advanced safety measures such as double containment systems, robust insulation and gas detection systems to reduce risks and ensure safe handling and storage of LNG on board.

SE-607 Floating LNG Terminal 3000 m3 by Seatech Engineering – a non propelled vessel that allows LNG bunkering when equipped with a tug/pusher

Moreover, multi-fuel bunkering vessels must accommodate a variety of fuel types, each with its own storage and handling requirements. Versatility is the key and requires innovative solutions to optimize space utilization to segregate cargoes and minimize the risk of cross-contamination. Flexible piping systems, separate storage tanks and dedicated refuelling stations are among the design features used to facilitate the efficient transfer of different fuels while maintaining operational integrity.

SE-615 Multifuel Bunkering Vessel designed by Seatech Engineering as a modular platform for the installation of various cargo containment systems, prepared for diesel, LNG, bioLNG, methanol, ammonia, and, in the future, liquid hydrogen

Efficiency is another important factor of the design process. Bunkering operations require manoeuvrability and responsiveness to minimize downtime for refuelled vessels. Designers optimize vessel layouts, propulsion systems and fuelling infrastructure to streamline operations and maximize throughput. Advanced propulsion technologies, such as dual-fuel engines and azimuth thrusters, increase flexibility and fuel economy, contributing to the overall efficiency of operations.

SE-608 LNG Low Air Draught Bunkering Vessel 5000 m3 visualisation, meeting the requirements of LNG-fuelled cruise ships, with high manoeuvrability and a modular diesel/gas-electric propulsion system for future conversion to alternative fuels such as methanol/hydrogen, design by Seatech Engineering

Environmental sustainability remains at the forefront of design considerations throughout the process. In addition to reduce emissions through cleaner fuels, design offices are exploring innovative solutions to minimize ship’s environmental impact. Hull optimization, waste heat recovery systems and ballast water treatment technologies are integrated into design to increase energy efficiency and minimize environmental impact.

SE-618 Shallow Draught LNG Feeder and Bunkering Vessel – an ideal solution for Baltic and North Sea harbours, characterized by dimensions allowing to pass through the Vistula Canal and reach the port of Elblag, design by Seatech Engineering

Seatech Engineering boasts an extensive portfolio of ready to use designs of LNG, diesel or methanol bunkering vessels, of diversified parameters and sizes. As part of ongoing projects, office provides comprehensive design services, including hybrid and multi-fuel solutions tailored to client requirements. Seatech develops vessel feasibility studies for correct connection with the selected propulsion system and provide optimization of operation time and fuel consumption. Seatech works with major suppliers of cargo handling, and ensures matching various fuel storage systems. In addition, design office has experience in so-called Small Scale LNG Units, including those fuelled with methanol, distillate diesel oil or residual diesel oil. The buckle to all support are brokerage services, providing support in selecting the most suitable shipyard with the resources to build the designed unit.

It is worth mentioning that our office offers implementation of projects that can be updated during the life cycle of the unit. For example – the propulsion system originally designed, based on the concept of “diesel/gas-electric” propulsion, can be replaced over time with, for example, fuel cells, once the technology is developed and ready for implementation. The same is with cargo storage and handling system. After 10, 20 or 30 years of operation, the LNG system can be replaced by a solution using methanol, ammonia or even hydrogen – explains Krzysztof Czerski.

In addition, an LNG bunkering vessel or multi-fuel unit can be designed by us for modular assembly based on various components manufactured by local, even small suppliers – adds.

The pressure for cleaner and more sustainable fuel alternatives continues to grow, but it takes time and investment to ensure rising resource levels. Efficient deployment of FSRUs, and bunkering and fuel-feeding vessels that support them, is one solution that addresses this challenge. Reaching out to competent engineers with the experience and necessary knowledge in the area of designing such units is within reach. Seatech Engineering remains ready to address these challenges, well aware of the complexity of the design process for the aforementioned vessels and the expectations and requirements of today’s rapidly changing market.