Ship design – challenges in contracting process (part II)

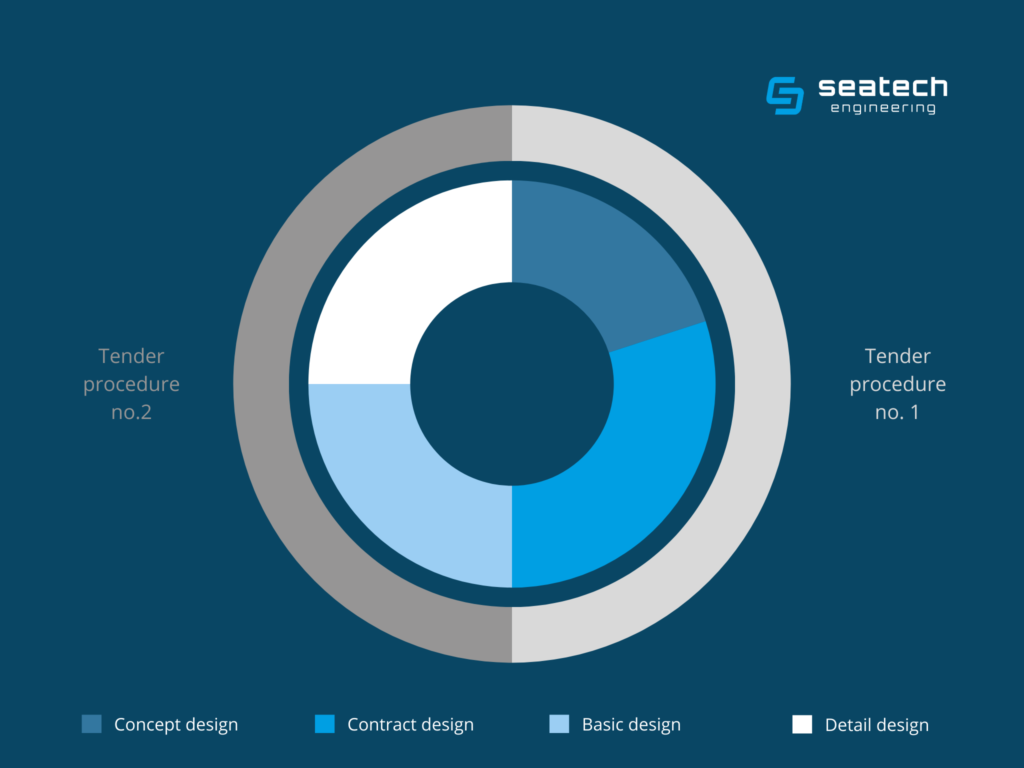

Diversified practices in the area of contracting ship design services affect the efficiency of project implementation, as discussed in the first part of the article. As we’ve recommended, the most beneficial solution is to divide contracting into two parts – first tender including concept and contract design, and second procedure covering basic design and workshop documentation of the ship. Following article will introduce the complexity of the design process and benefits of implementing abovementioned division of contracting for all interested parties, i.e. the buyer, the design office and the shipyard.

Different buyers – different expectations

The primary goal of the ship design process is to provide the owner with a vessel that meets his expectations in terms of performance, functionality and investment costs, and thus fits into assumed return on investment. Buyers demands vary depending on business specifics the ship is intended to serve. For those operating in transport industry, deadweight issues are the key. For passenger ships, factors such as capacity, travel comfort, cabins volume or deck space are important. For research vessels, on the other hand, the requirements of handling specialized equipment with specific dimensions and utility functions are relevant. In addition, due to reduced investment and operating costs expectations, owners demands regarding vessel’s dimensions occur, and the global drive for sustainable development of the maritime industry additionally generates requirements for energy efficiency and emissions minimization. Such diverse and extensive guidelines as to functions, equipment or dimensions the vessel must fulfill, are often in conflict with technical capabilities of the ship expected by the owner. Therefore, it is extremely important to eliminate any potential conflicts at the initial stage of the project. Requirements should be defined very precisely and subjected to joint verification, between the owner and the design office, already at the stage of concept and contract design of the vessel.

A ship as a complex structure

Because of its operation on the water, a ship is a far more complex structure than, for example, a building, which forces the need to take into account many additional variables. Unlike shore-based facilities, which are connected to an existing utility network, ship designers must provide all necessary infrastructure that will enable a vessel to operate independently on the open sea. This means that in addition to assure equipment, related to the function performed by the ship, and accommodation facilities, the vessel must include space for a power plant, sewage collection systems, a thermal power plant, heating and ventilation systems and potable water supplies. The lump of the vessel, moreover, must be designed to accommodate and carry all this necessary infrastructure. In addition, designers must plan an appropriate shape of the vessel to allow assumed speed and guarantee proper stability in difficult weather conditions. The vessel must also have the ability to operate on defined distances, anticipating necessary amount of fuel, water and food without having to refill them for days.

However, simply providing necessary infrastructure of the ship is not enough. It must be designed in accordance with applicable regulations – not only local, but also international, including standards of classification societies and regulations of international maritime institutions and UN agencies, defining safety and environmental standards for vessels.

Reliable input data as the foundation of the design process

Cooperation from the moment of creating guidelines, verifying the assumptions at the stage of concept design and feasibility study are the key. This is why the contracting of vessel’s design should be divided into two parts mentioned before – in the first stage concept and contract design done by the design office in cooperation with the owner itself, and in the second stage the implementation of class design and workshop documentation with the participation of selected shipyard.

What’s important, the cooperation between the buyer and the designers must take place in an organized manner, with clearly defined roles and responsibilities. As a number of compromises have to be made, crucial to the first phase is the ability of the owner to make quick and efficient decisions. Competent and decisive people must therefore be involved in the process on both sides. If the buyer doesn’t have necessary expertise to implement the project and ensure a smooth decision-making process within its resources, it’s always an option of use experienced external consultants or, more formally, contract engineers. The owner doesn’t need to know the detailed requirements for the vessel with respect to necessary regulations, but he should clearly define the expected functions of the ship and the operational profile, while being aware of the limitations that physics imposes on vessels and be ready to make compromises. Detailed ship design knowledge is on designers’ side, but it is the ship owner who is responsible for defining his requirements correctly, which are verified by the design office within the contract design stage. Also in the area of preparing the subsequent legal documentation, it is worthwhile to use the support of law companies specializing in the development of contracts for the maritime industry. Such solutions guarantee a substantive discussion at the stage of creating the assumptions of the entire project, and this impacts minimizing risks during next project stages.

An extreme but common example in tender procedures is to impose in the documentation rigid parameters of the vessel, such as length, width or draught, while specifying the expected speed and a list of necessary equipment of the vessel. Such owners approach simply closes options for engineers to find design solutions, and it is sometimes impossible to merge all those variables. As a result, exceptions from the contract provisions are necessary, and the vessel ends up coming out more expensive and varying from unverified design assumptions.

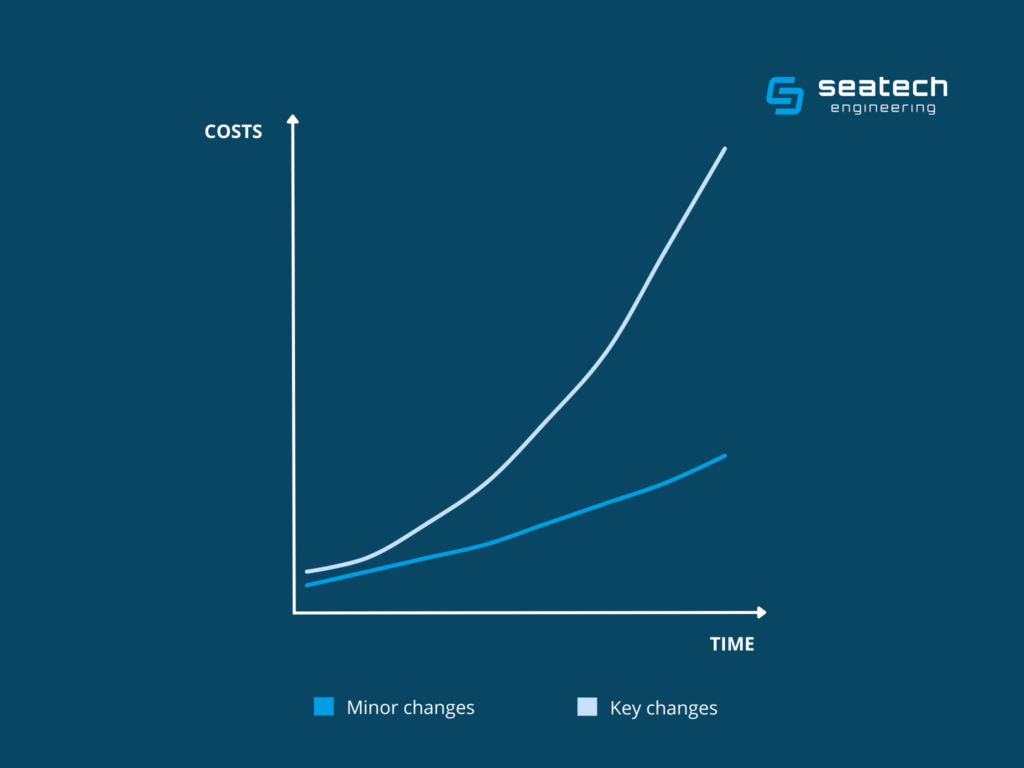

Increase in the cost of implementing changes over time depending on the relevance of the change

Increase in the cost of implementing changes over time depending on the relevance of the change

Moving away from ‘design and build’ formula

In our opinion, carrying out design work under ‘design and build’ formula from the initial project stage is a wrong approach, most likely due to lack of understanding of the design process stages by the owner, lack of competence of those involved in the project on his side required to evaluate, verify and make important decisions, and unwillingness to take responsibility for the quality of the input data. A more reasonable and significantly less risky solution for each party, in our opinion, is to base the design of the vessel on reliably prepared assumptions, i.e. the implementation of the concept and contact design of the ship as a base for further decisions and the valuation of the vessel by the shipyard in the second separate contract procedure. This is a proven and widely used, mainly outside Poland, method of developing the design process, which does not eliminate all risks, but significantly reduces them and allows the project to be implemented within the budget and according to agreed schedule.

Breakdown of the design process in relation to the relevance of each stage

Breakdown of the design process in relation to the relevance of each stage

In order to avoid later problems and minimize costs, it is reasonable to clarify critical contradictions and define necessary adaptations already at the contract stage of the project. Changes here include verifying main assumptions, developing general arrangement of the vessel, conducting necessary calculations, inspecting necessary equipment or clarifying the appearance of the ship. It is only in the second tender stage, once involving selected shipyard, that the individual components, i.e. construction, deck plans or interior layouts and equipment, are refined based on widely understood regulations. Incorrectly selected and unverified parameters and functions of the vessel, in case of including the entire design process in one tender and implementing ‘design and build’ formula from the initial phase, generates problems in developing the project in accordance with the specification, under assumed budget and within planned timeframe. Hence our indication to engage a design office at the concept stage, but through a separate additional procurement.

Ship design – the art of compromise and decision-making

The process of designing a ship is a complex and multifaceted assignment that requires careful examination, the ability to make compromises and close cooperation between the owner, the design office and the shipyard. The key stage is the implementation of ship’s concept and contract guidelines, as fundamental decisions are made here regarding technical, financial and performance assumptions, which have a great impact on the later course of the project. A reliably prepared initial and contract design are the foundation of success, enabling the implementation of a functional vessel, reliable estimation of costs, execution time and minimization of risks associated with the construction of the ship.

The differences between commercial and public projects, as well as the diversification of contracting practices in different countries, indicated the importance of a correct approach in the design process organization and its appropriate allocation within the tender proceedings, which should be based on precise, well-verified input data and a reliable distribution of responsibility on various stages of implementation. In the context of increasing requirements related to energy efficiency, safety and environmental protection, as well as sustainable development of the maritime industry, it is worth investing in a well-defined and guided design process, based on the experience of market-leading design offices.